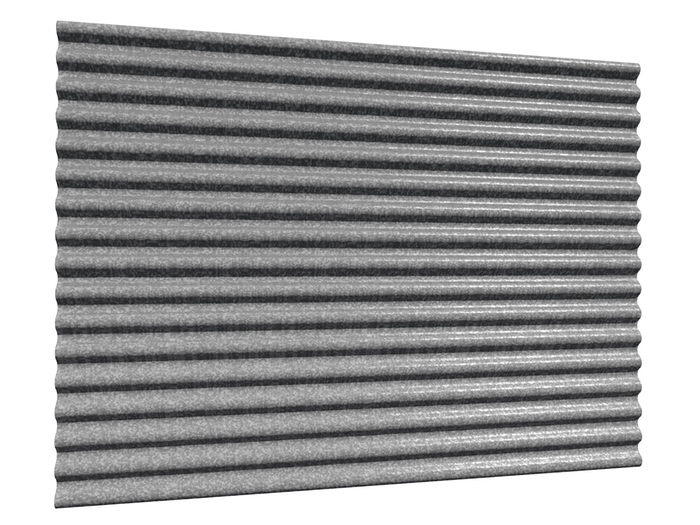

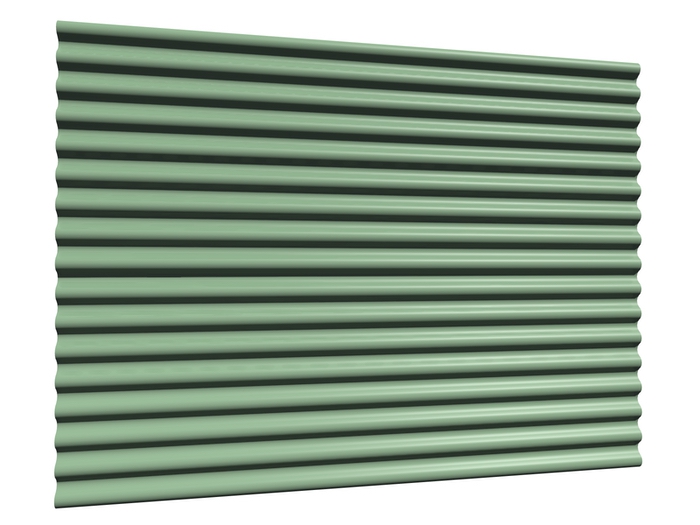

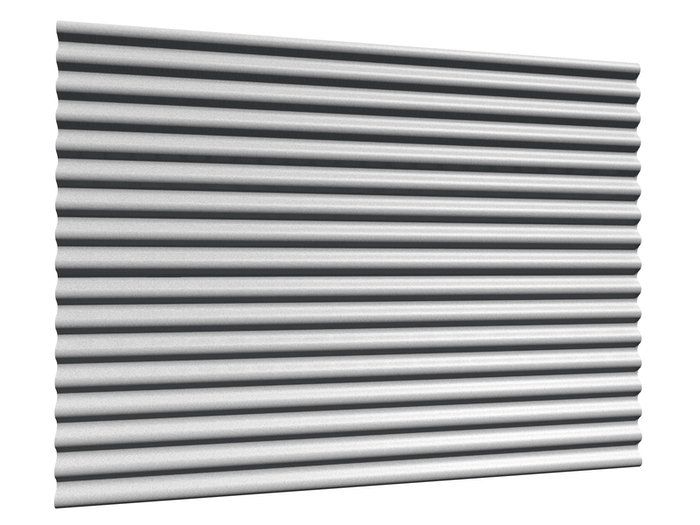

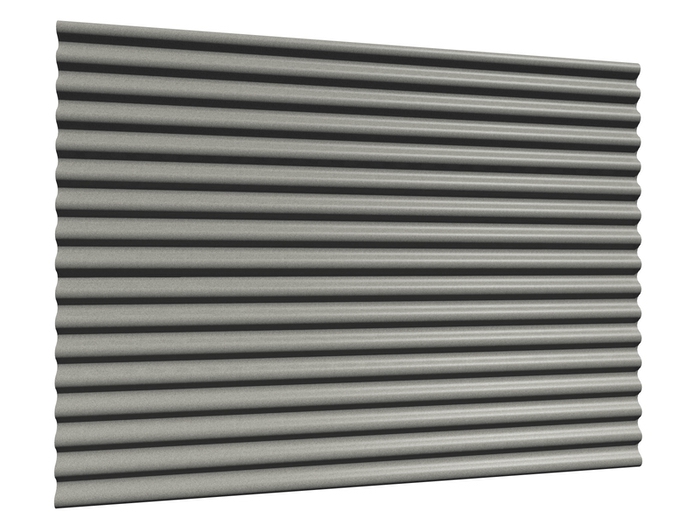

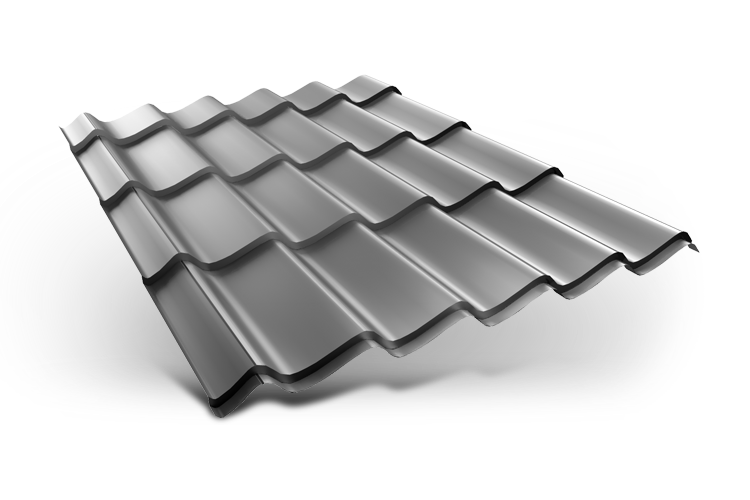

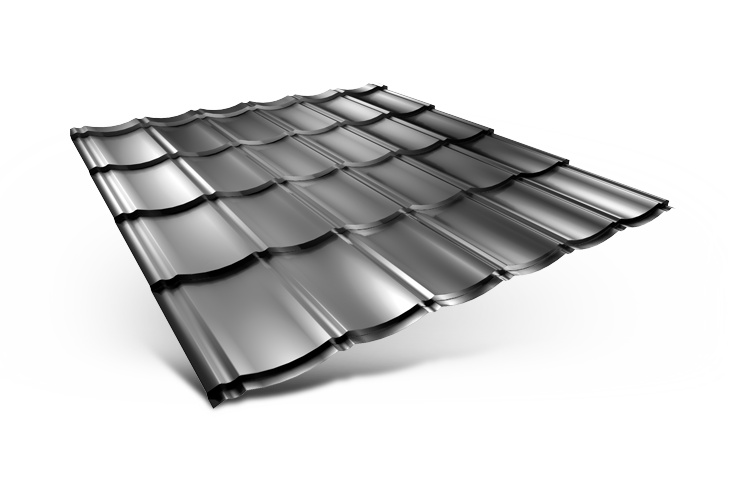

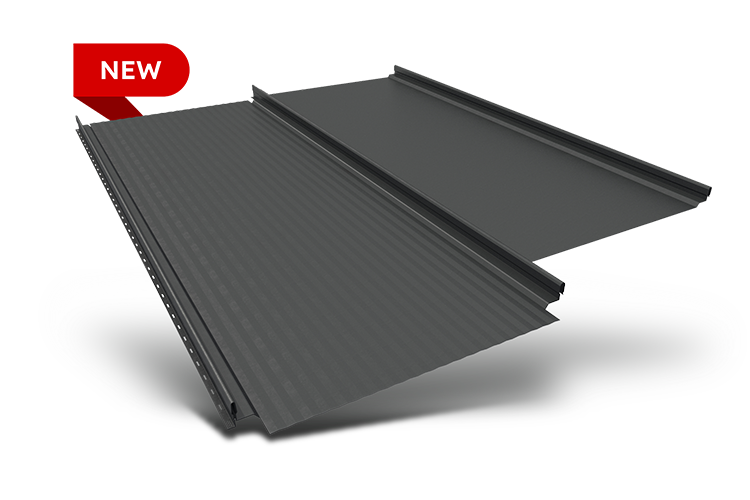

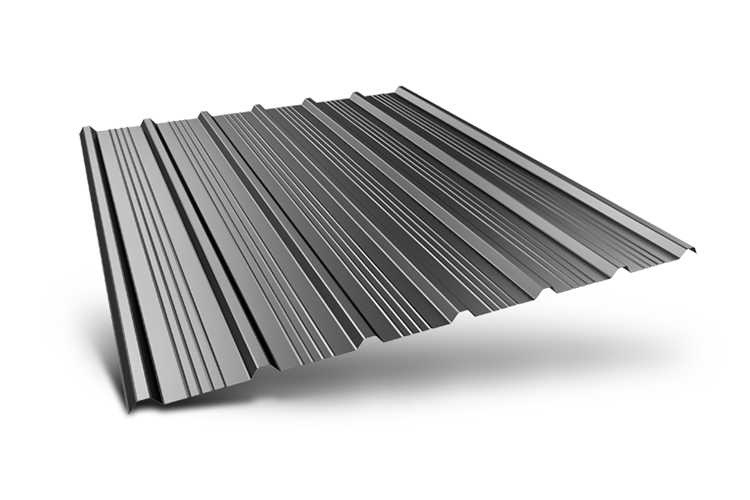

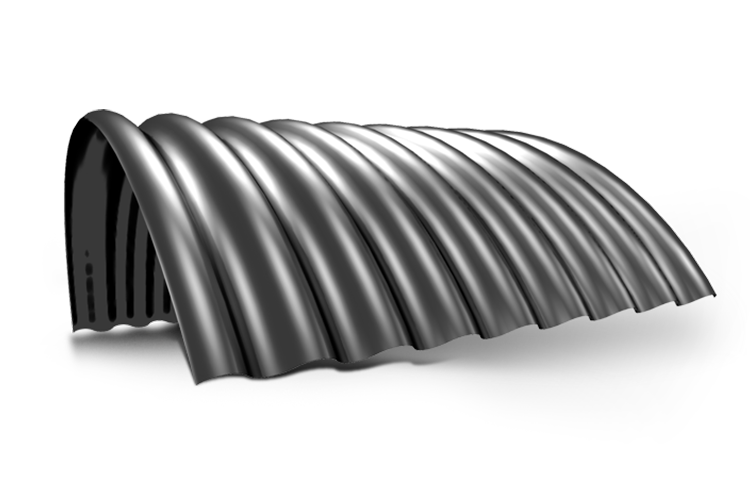

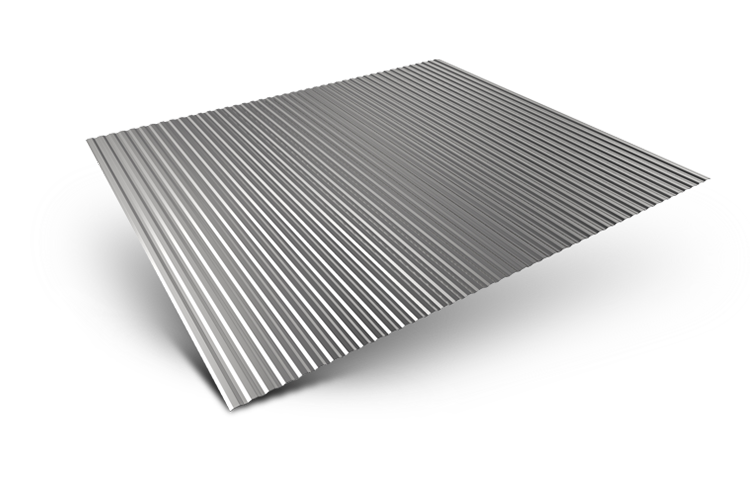

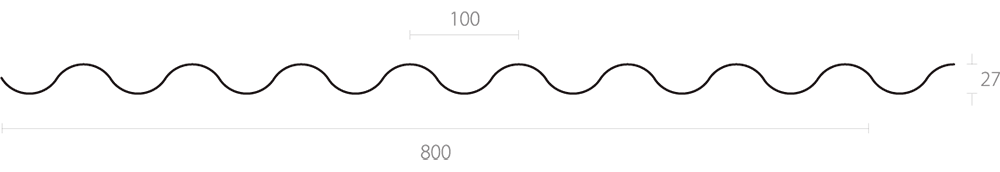

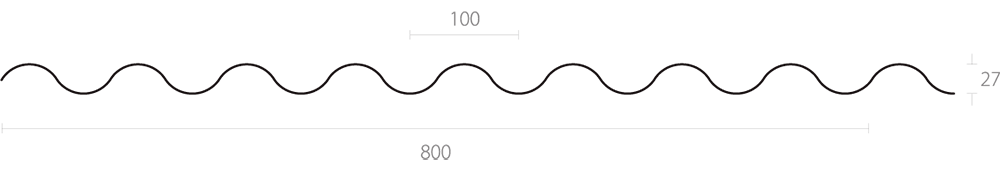

PAN-S27

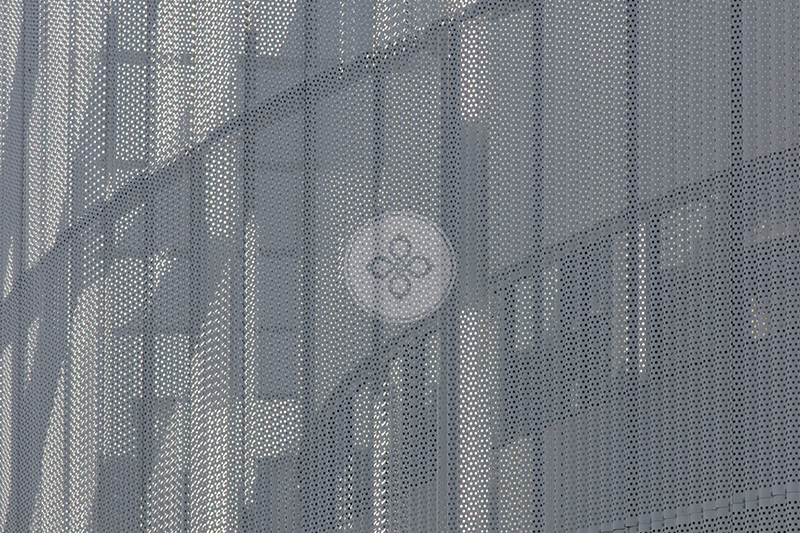

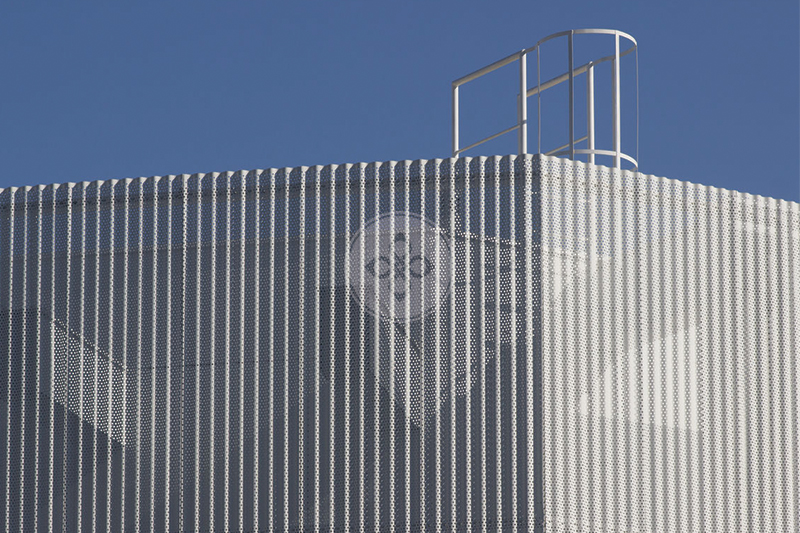

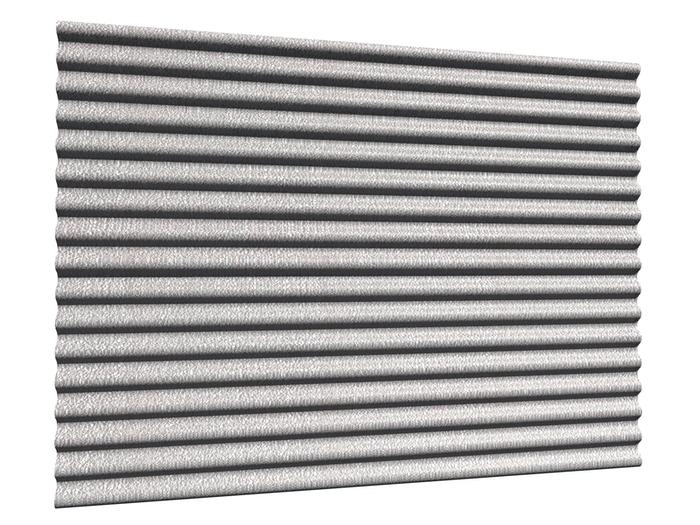

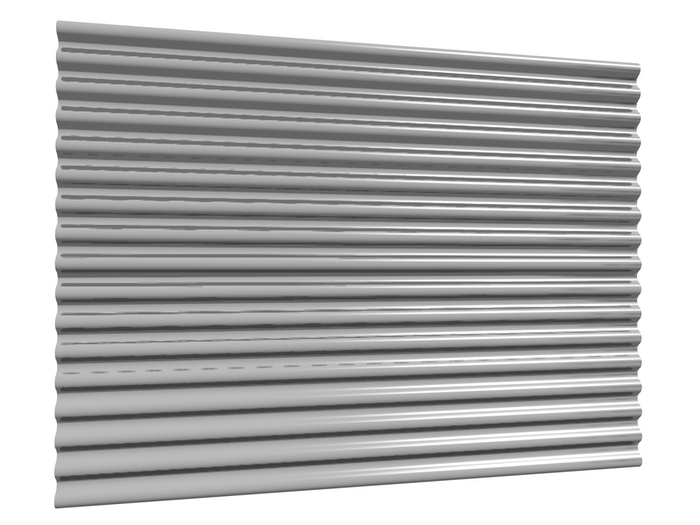

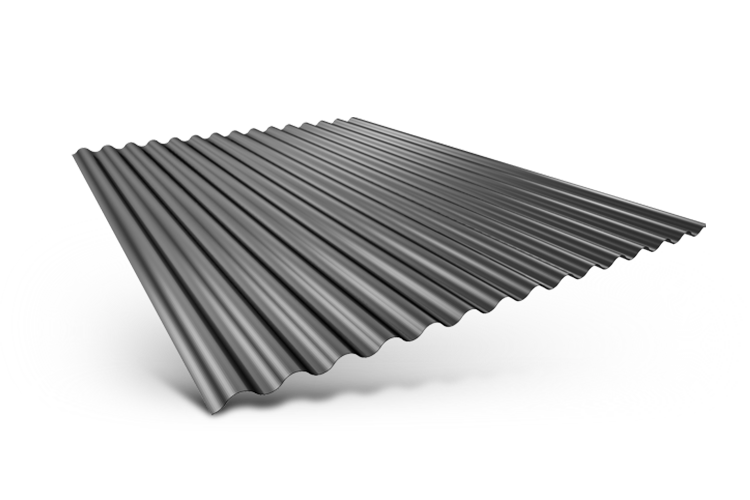

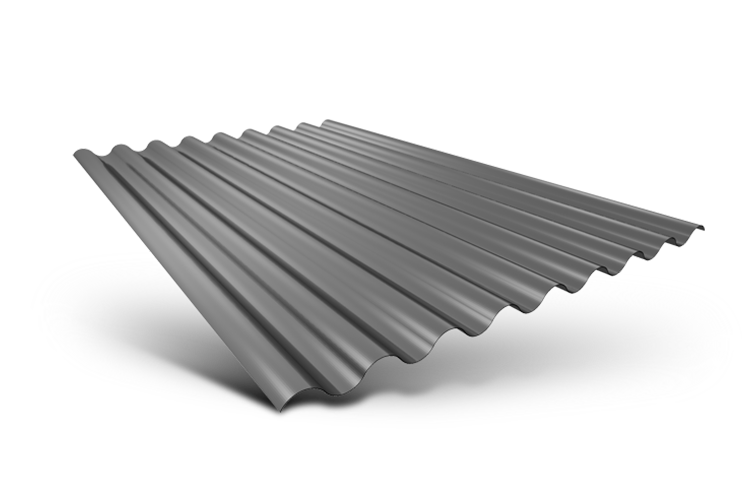

Pan-S27 sinusoidal profiled sheet metal which follows the latest trands in architecture and building construction. It stands out from the standard trapezoidal profiles with is harmonius curves and it makes the facades and roofs true works of art. Curved profile lines provide easy watter run-off and dust free surfaces.

![]()

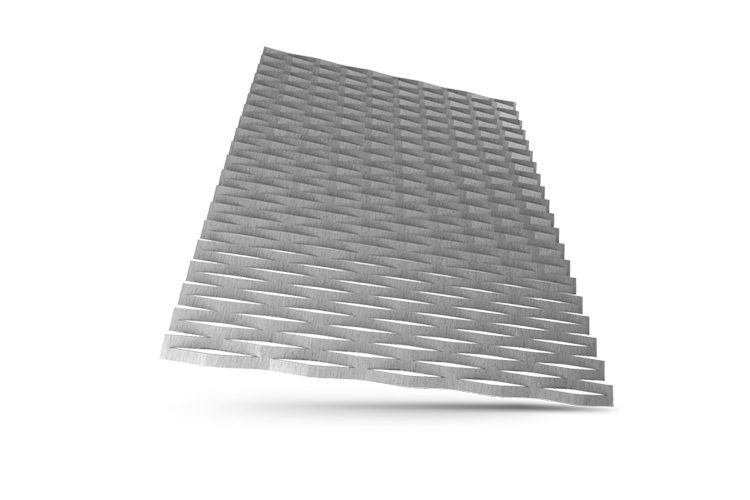

Product can be produced from transparent polycarbonate

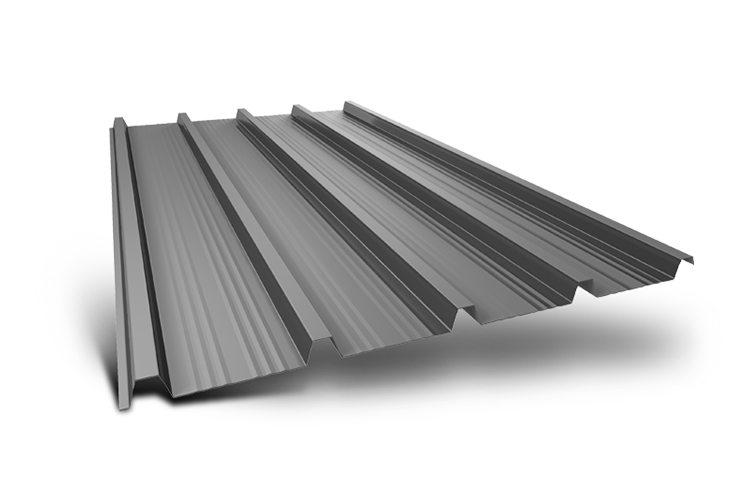

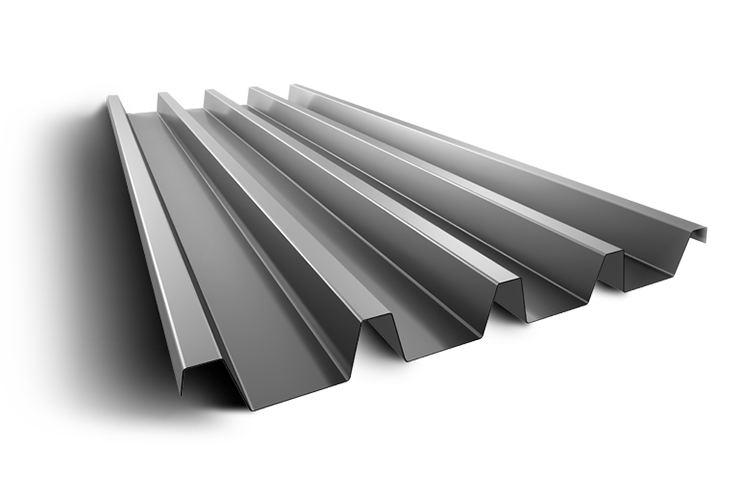

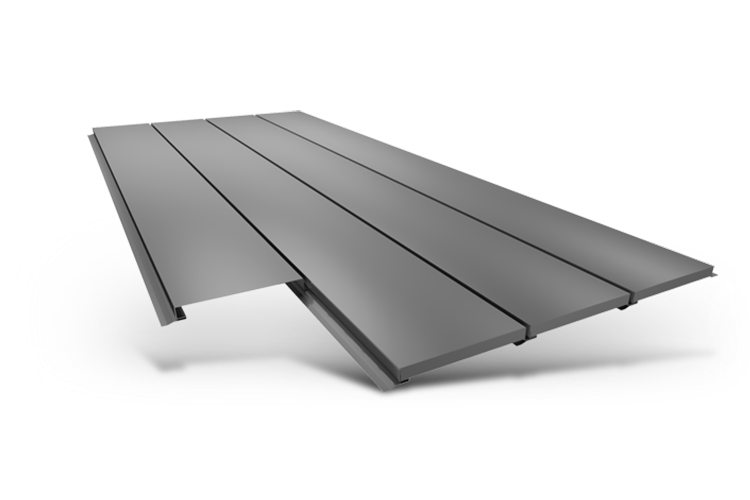

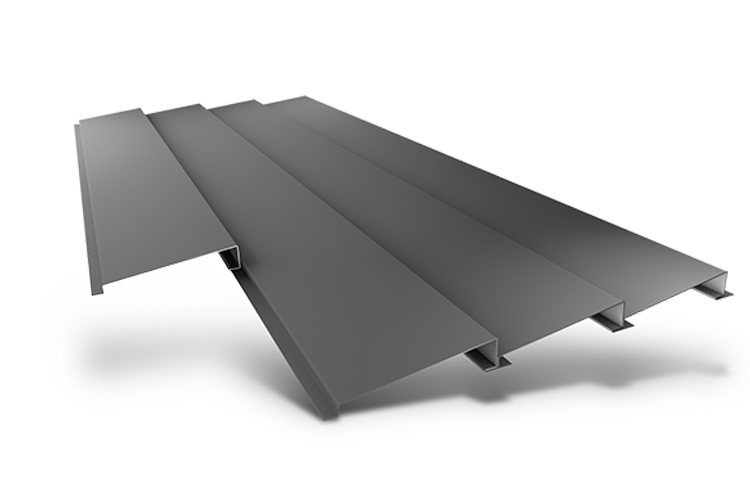

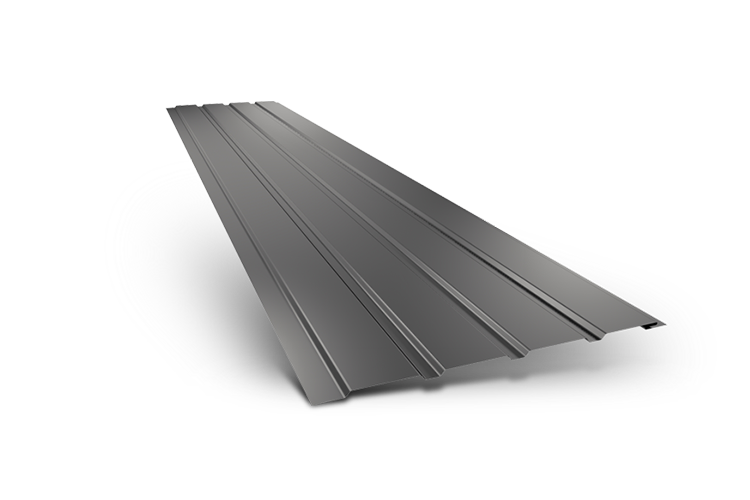

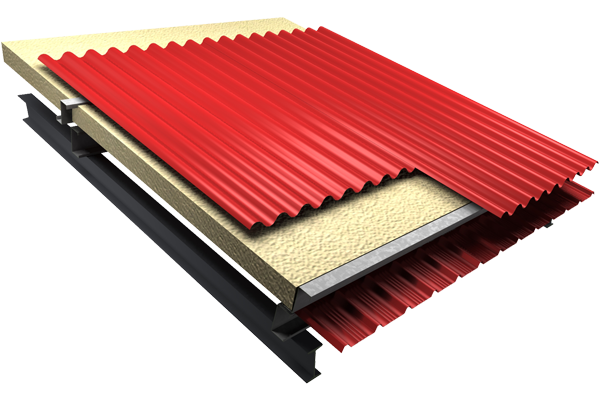

ROOF PROFILING

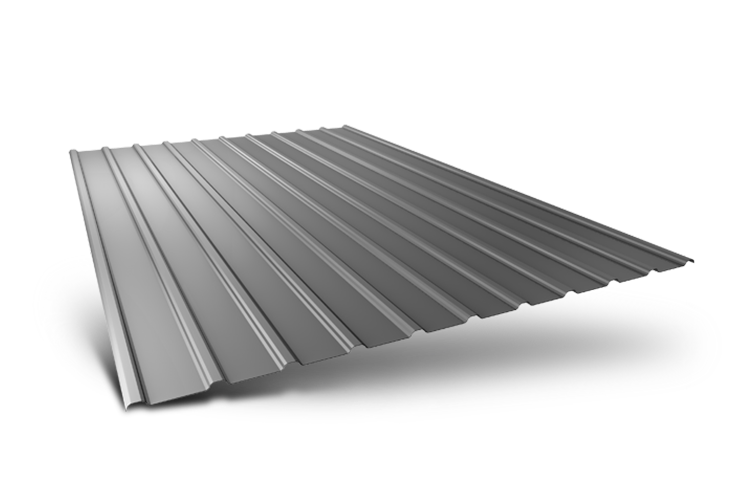

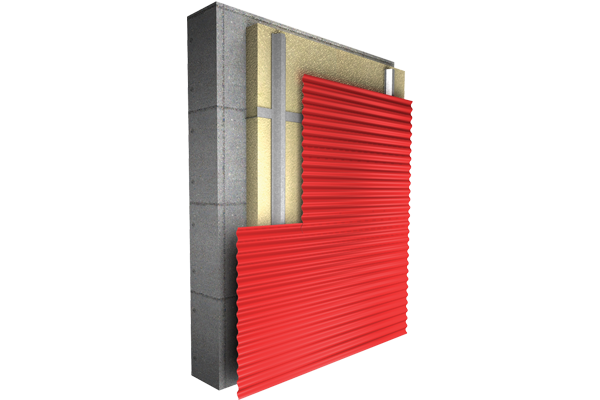

FACADE PROFILING

| Profile length | Profile range | Steel thickness | Aluminum thickness |

| 0,2 - 9 m | do 2,3 m | 0,5 - 0,8 mm | 0,7 - 1,0 mm |

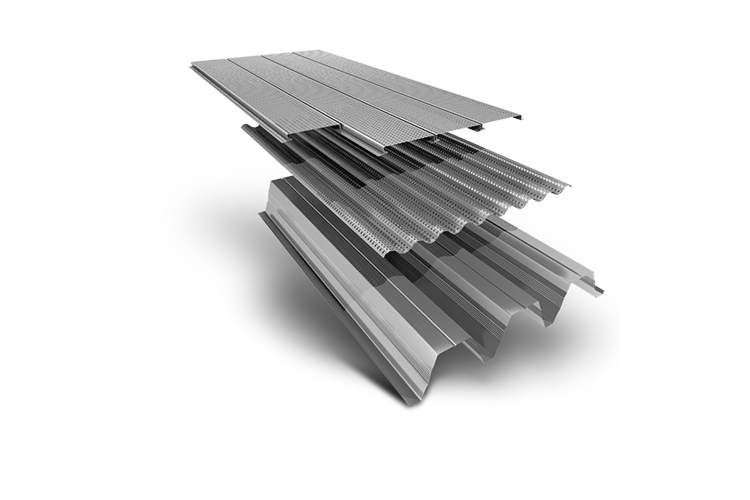

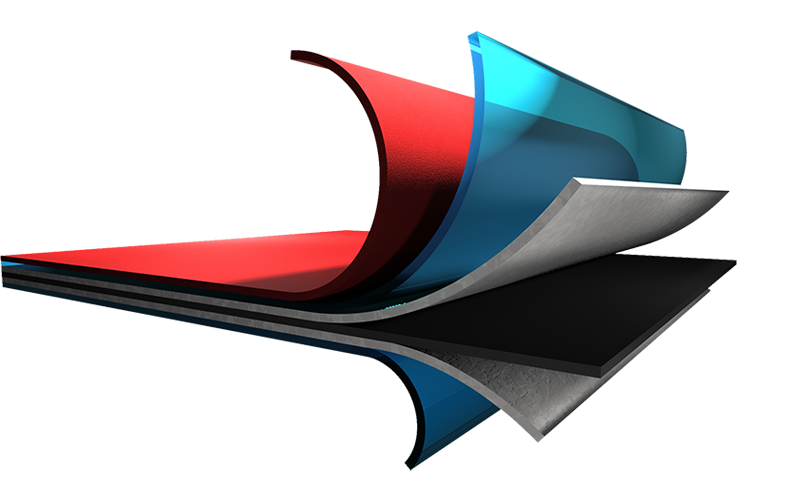

Protective layers

- Polyester coating 20μ

- Primer 7μ

- Zinc coating 140 gr/m2

- Steel base DX51 (0,5mm)

* The values can be changed upon request

All materials used in Pan Komerc production has unique attest for quality and technical characteristics that guarantees the origin, physical and chemical properties of metal sheet. In this way, keeping a complete insight into all the features of the material, customers are guaranteed that demanded material is received.

Product features

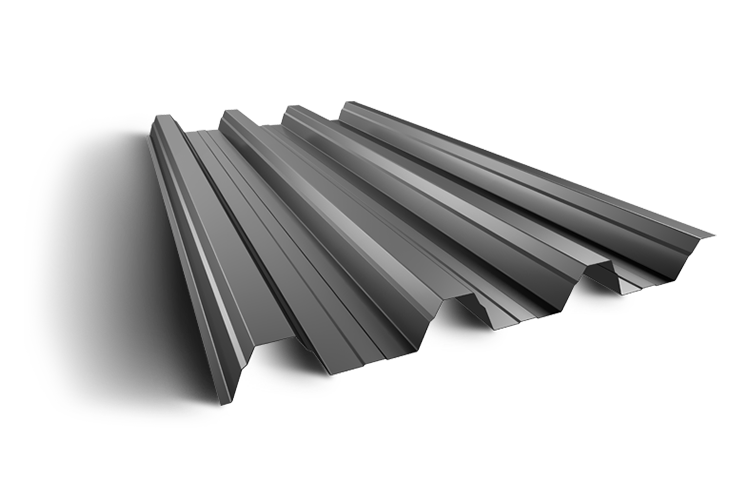

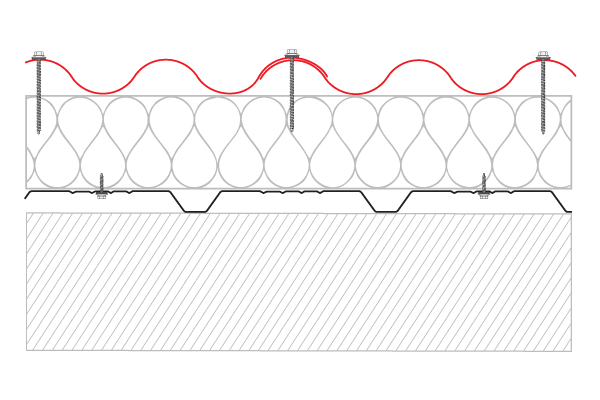

ROOF PROFILING

INSTALLATION EXAMPLE

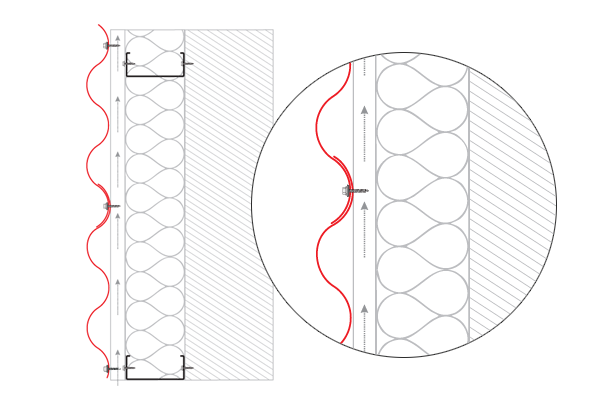

FACADE PROFILING

HORIZONTAL INSTALLATION EXAMPLE

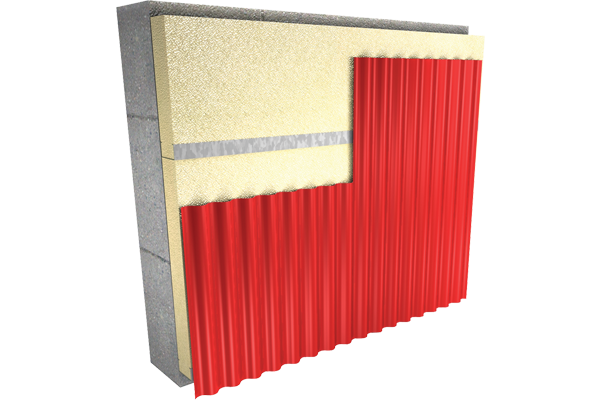

FACADE PROFILING

VERTICAL INSTALLATION EXAMPLE

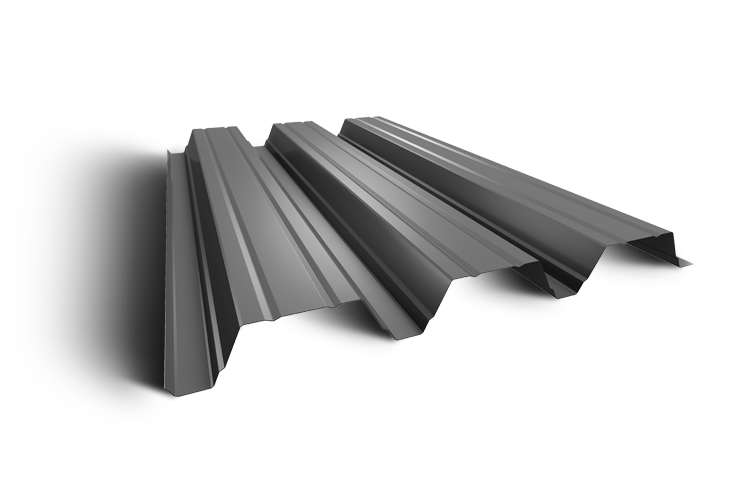

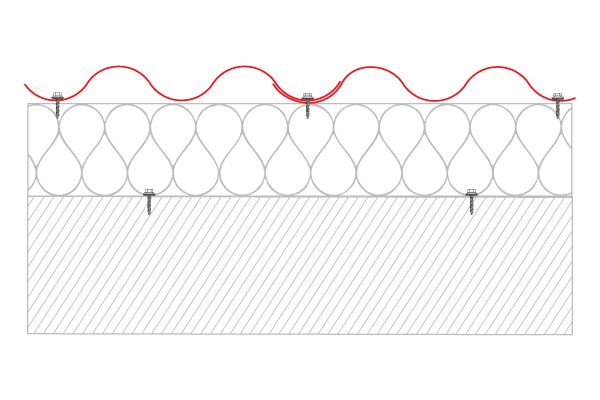

ROOF PROFILING

INSTALLATION CROSS SECTION

FACADE PROFILING

HORIZONTAL INSTALLATION CROSS SECTION

FACADE PROFILING

VERTICAL INSTALLATION CROSS SECTION

| Pan-S27 - steel | |||||

| Thickness (mm) |

Weight m2 | Load (kN/m2) |

Support beam span (l) for max deflection fmax ≤ l/200 and allowed tension Σ fdoz = 14 kN/cm2 | ||

| 0.60 | 6.0 | 1.00 | 1.80 | 2.41 | 2.24 |

| 1.25 | 1.67 | 2.15 | 2.08 | ||

| 1.50 | 1.57 | 1.97 | 1.95 | ||

| 1.75 | 1.49 | 1.82 | 1.85 | ||

| 0.80 | 8.0 | 1.00 | 1.97 | 2.68 | 2.46 |

| 1.25 | 1.83 | 2.48 | 2.28 | ||

| 1.50 | 1.72 | 2.26 | 2.15 | ||

| 1.75 | 1.64 | 2.10 | 2.04 | ||

| 1.00 | 10.0 | 1.00 | 2.13 | 2.89 | 2.65 |

| 1.25 | 1.97 | 2.68 | 2.46 | ||

| 1.50 | 1.86 | 2.52 | 2.31 | ||

| 1.75 | 1.76 | 2.33 | 2.20 | ||

| 1.20 | 12.0 | 1.00 | 2.26 | 3.07 | 2.81 |

| 1.25 | 2.10 | 2.85 | 2.61 | ||

| 1.50 | 1.97 | 2.68 | 2.46 | ||

| 1.75 | 1.87 | 2.55 | 2.33 | ||

| 1.50 | 15.0 | 1.00 | 2.43 | 3.30 | 3.03 |

| 1.25 | 2.26 | 3.07 | 2.81 | ||

| 1.50 | 2.13 | 2.89 | 2.65 | ||

| 1.75 | 1.93 | 2.74 | 2.51 | ||

| Pan-S27 - aluminium | |||||

| Thickness (mm) |

Wight m2 | Load (kN/m2) |

Support beam span (l) for max deflection fmax ≤ l/200 and allowed tension Σ fdoz = 14 kN/cm2 | ||

| 0.60 | 2.03 | 1.00 | 1.24 | 1.64 | 1.55 |

| 1.25 | 1.16 | 1.47 | 1.44 | ||

| 1.50 | 1.09 | 1.34 | 1.35 | ||

| 1.75 | 1.03 | 1.24 | 1.29 | ||

| 0.70 | 2.41 | 1.00 | 1.30 | 1.75 | 1.62 |

| 1.25 | 1.21 | 1.59 | 1.51 | ||

| 1.50 | 1.14 | 1.44 | 1.42 | ||

| 1.75 | 1.08 | 1.33 | 1.35 | ||

| 0.80 | 2.40 | 1.00 | 1.37 | 1.86 | 1.70 |

| 1.25 | 1.27 | 1.69 | 1.59 | ||

| 1.50 | 1.20 | 1.54 | 1.49 | ||

| 1.75 | 1.14 | 1.43 | 1.41 | ||

| 1.00 | 3.37 | 1.00 | 1.47 | 2.00 | 1.83 |

| 1.25 | 1.37 | 1.86 | 1.70 | ||

| 1.50 | 1.29 | 1.72 | 1.60 | ||

| 1.75 | 1.22 | 1.59 | 1.52 | ||

| 1.50 | 5.06 | 1.00 | 1.67 | 2.29 | 2.10 |

| 1.25 | 1.57 | 2.13 | 1.95 | ||

| 1.50 | 1.47 | 2.00 | 1.84 | ||

| 1.75 | 1.40 | 1.90 | 1.74 | ||

Downloading documents