![]()

Product can be produced from transparent polycarbonate

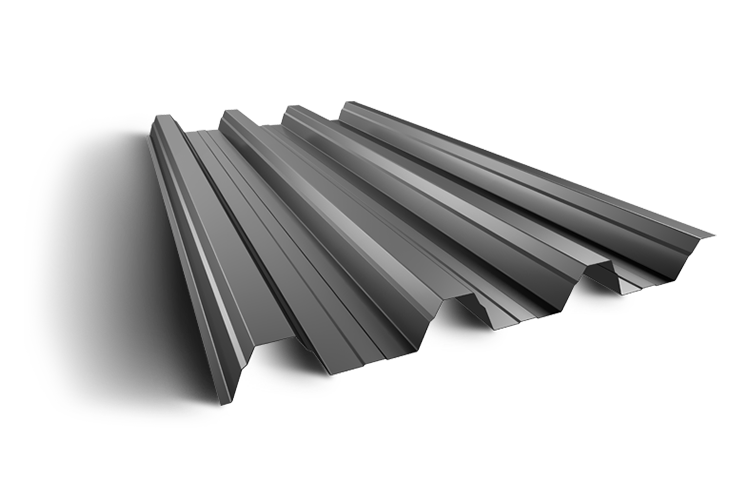

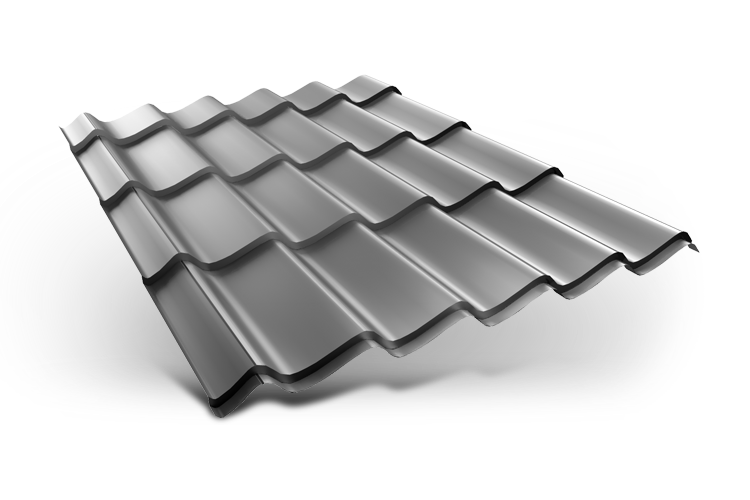

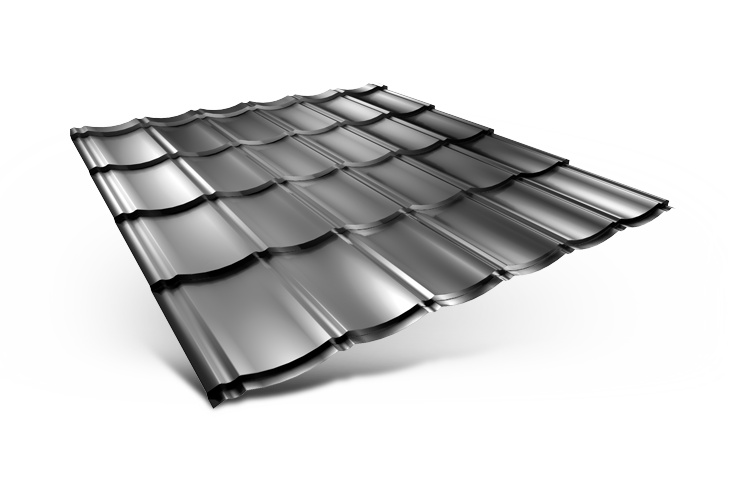

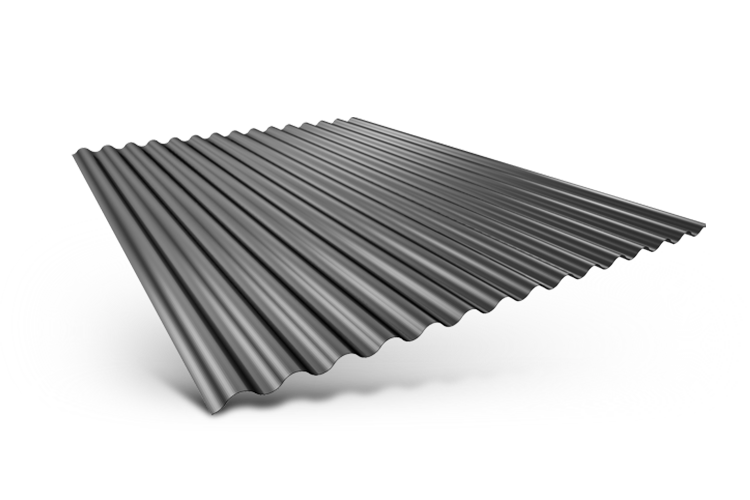

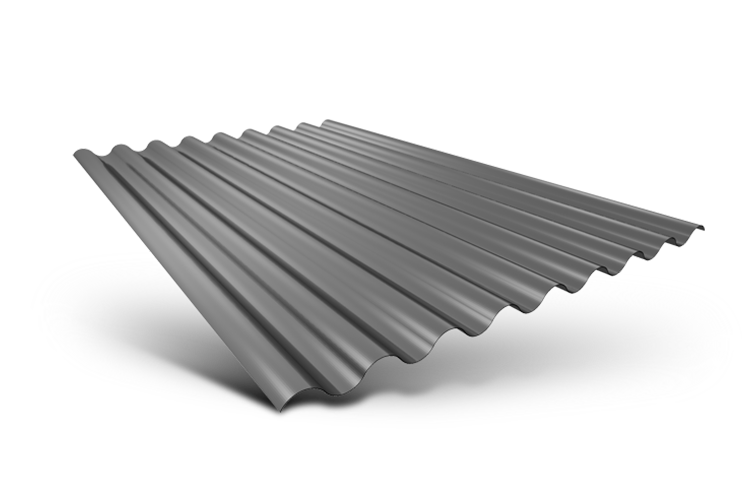

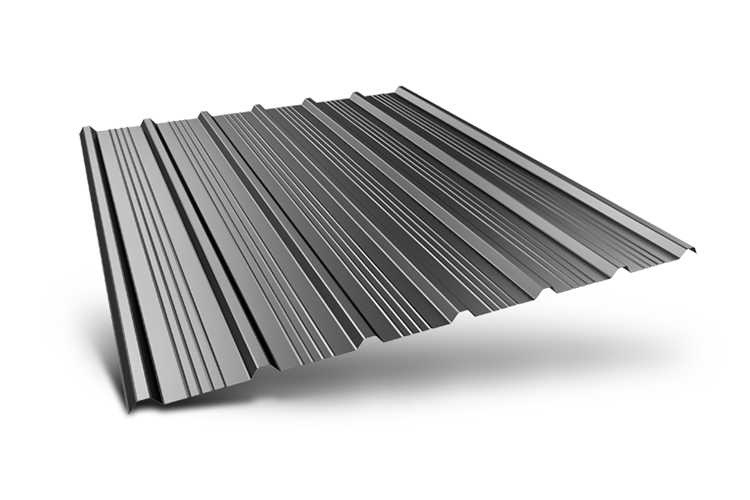

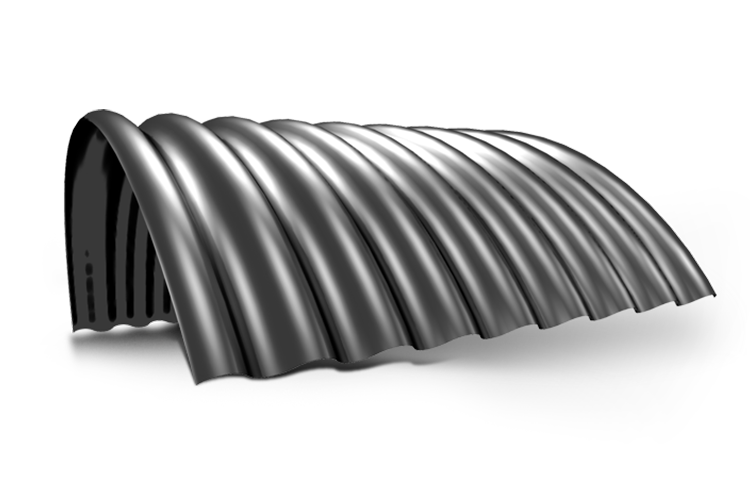

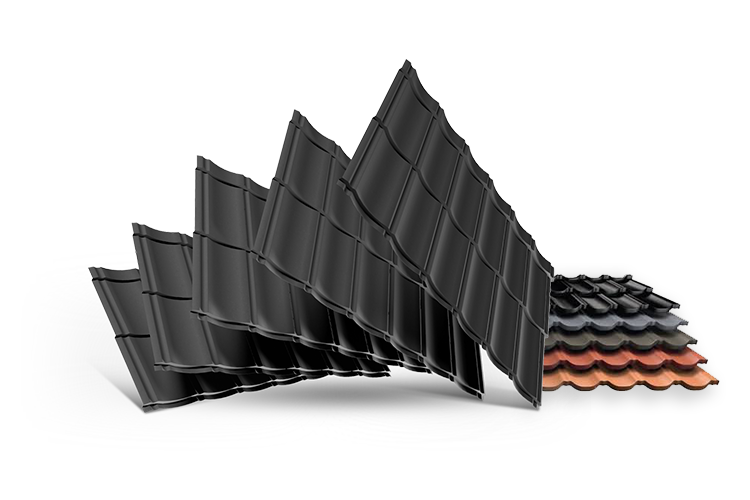

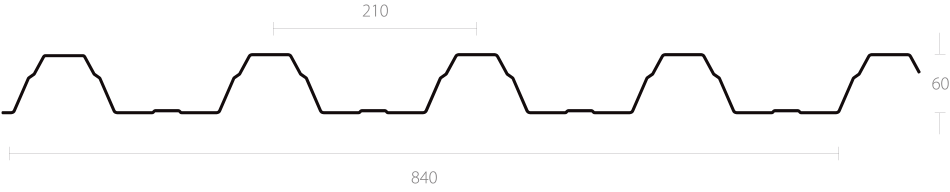

ROOF PROFILING

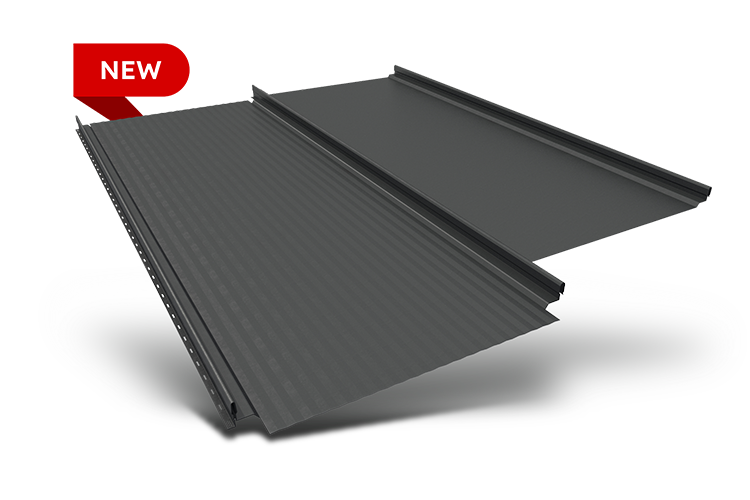

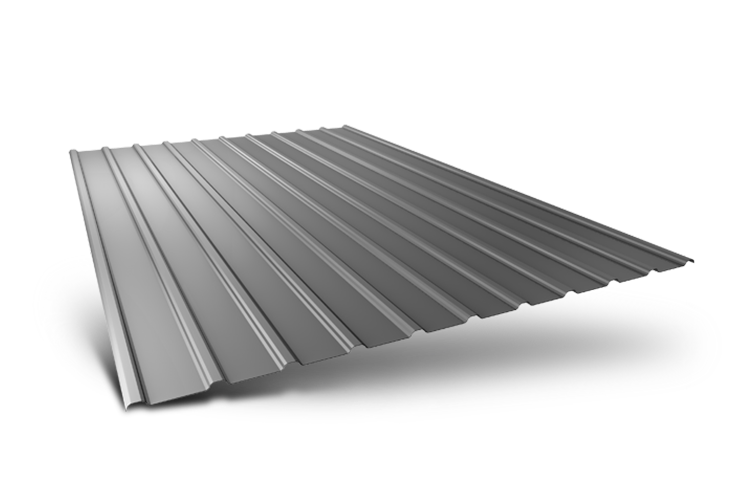

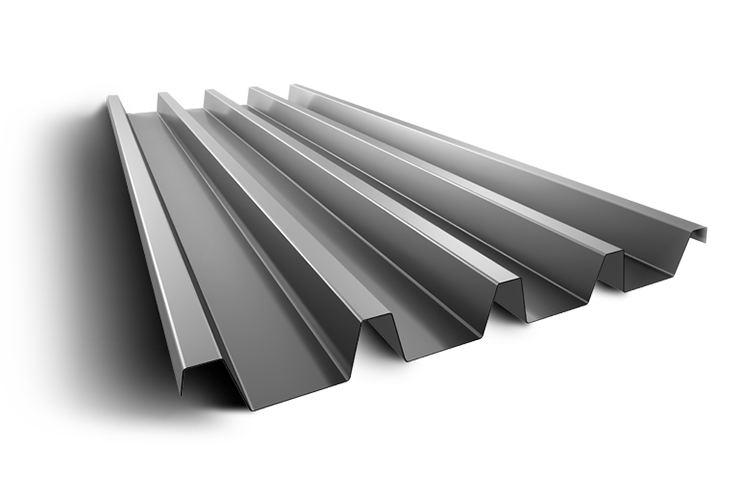

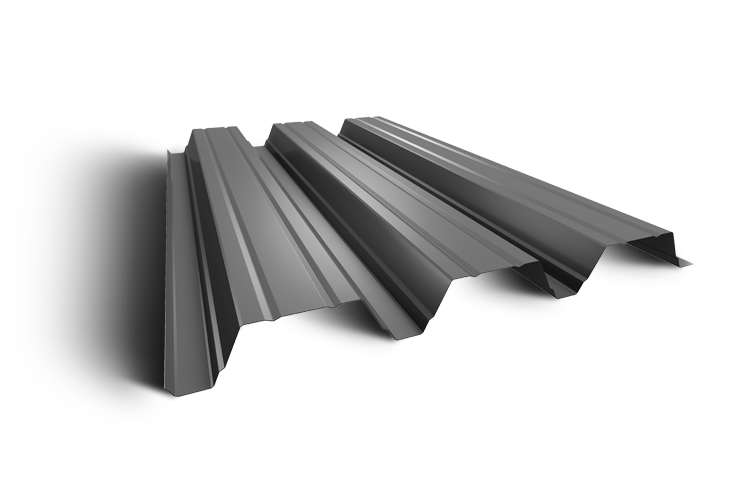

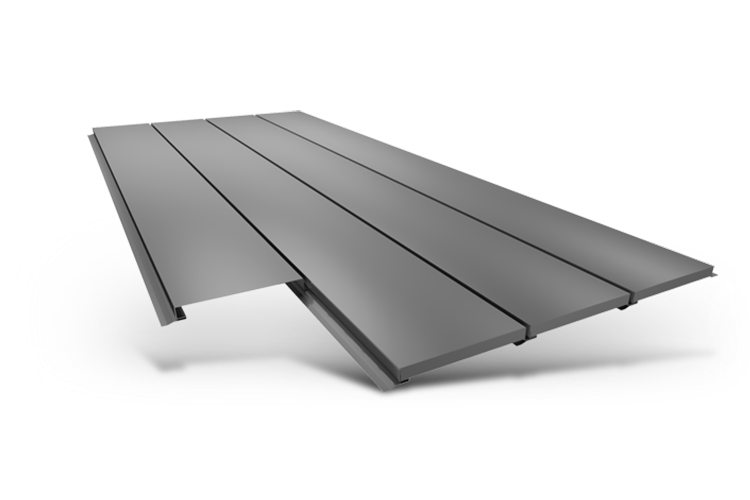

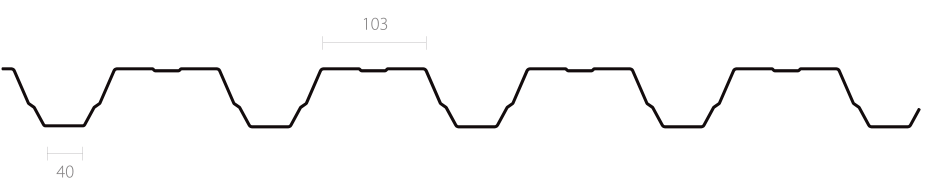

FACADE PROFILING

| Profile length | Profile range | Steel thickness | Aluminum thickness |

| 0,5 - 17 m | do 4 m | 0,5 - 1,0 mm | 0,6 - 1,0 mm |

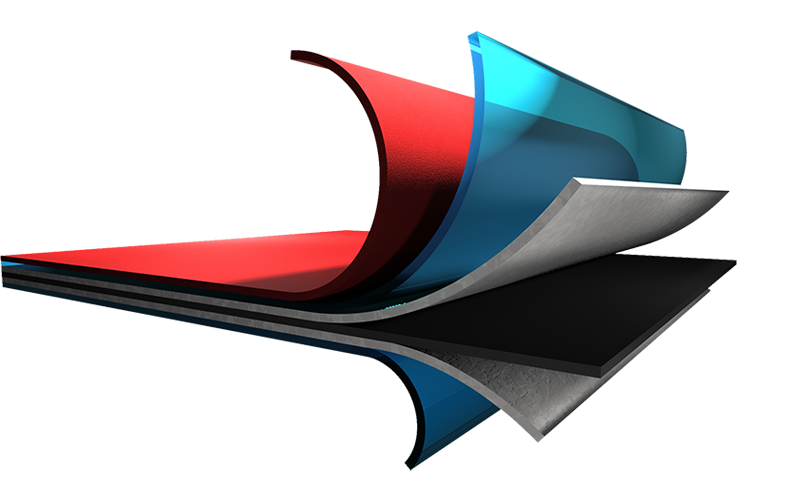

Protective layers

- Polyester coating 20μ

- Primer 7μ

- Zinc coating 140 gr/m2

- Steel base DX51 (0,5mm)

* The values can be changed upon request

All materials used in Pan Komerc production has unique attest for quality and technical characteristics that guarantees the origin, physical and chemical properties of metal sheet. In this way, keeping a complete insight into all the features of the material, customers are guaranteed that demanded material is received.

Product features

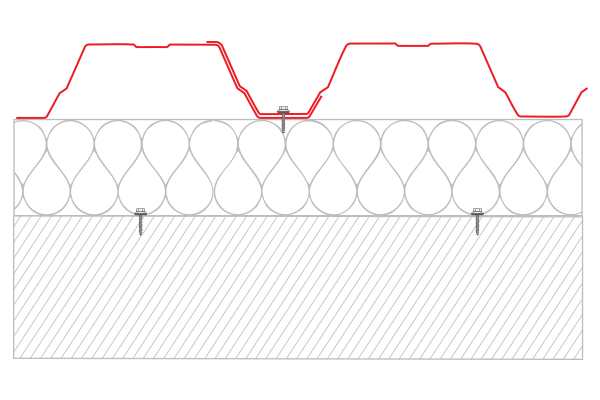

ROOF PROFILING

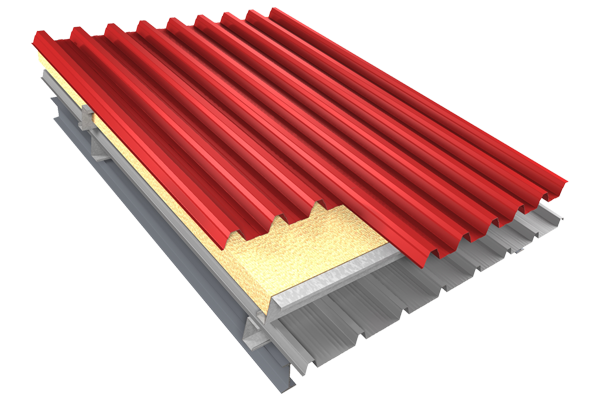

INSTALLATION EXAMPLE

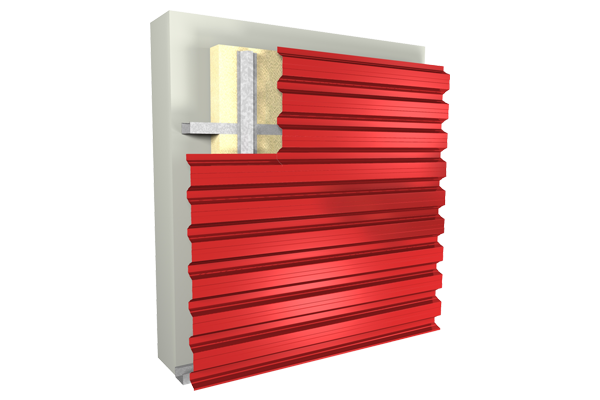

FACADE PROFILING

HORIZONTAL INSTALLATION EXAMPLE

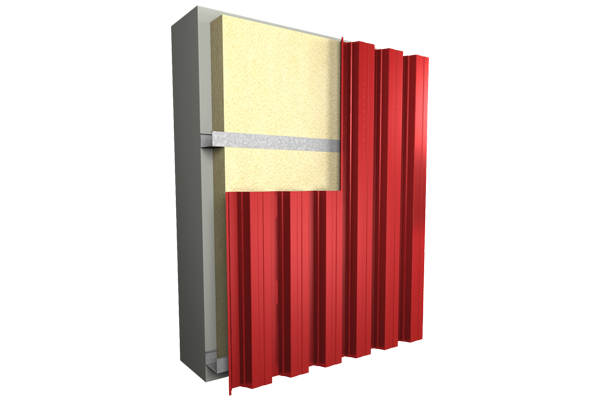

FACADE PROFILING

VERTICAL INSTALLATION EXAMPLE

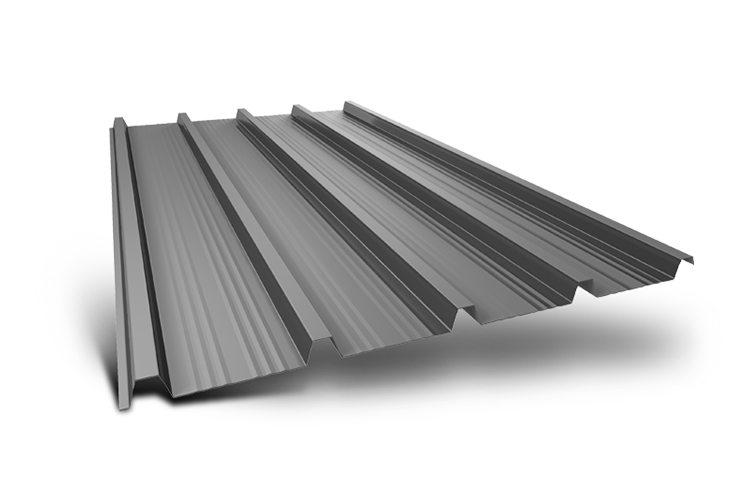

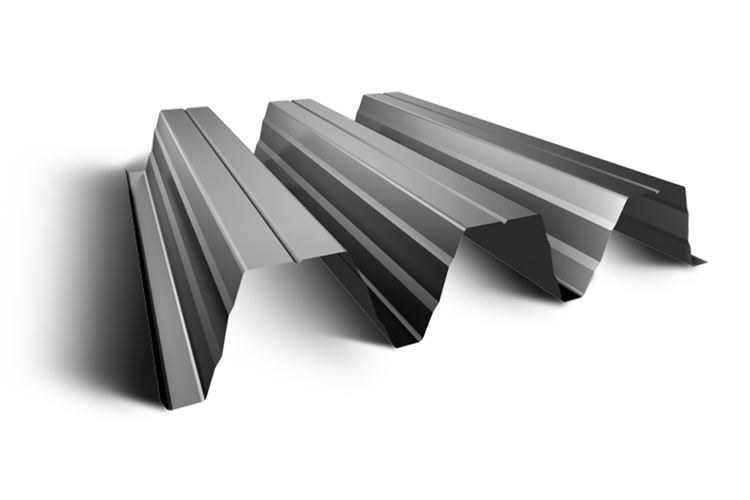

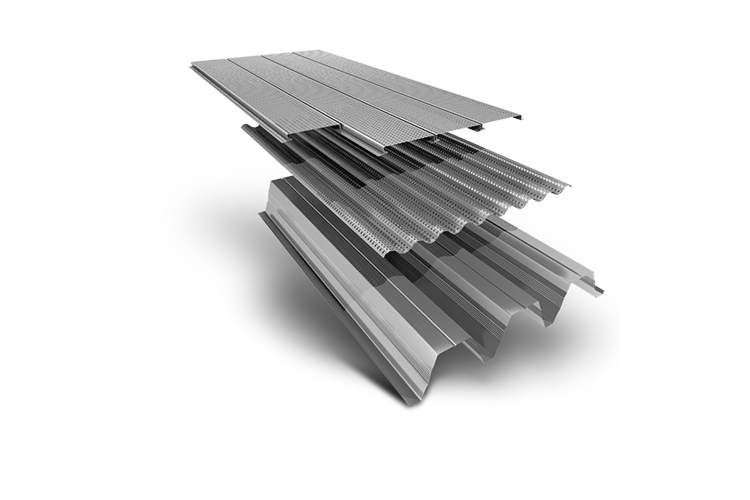

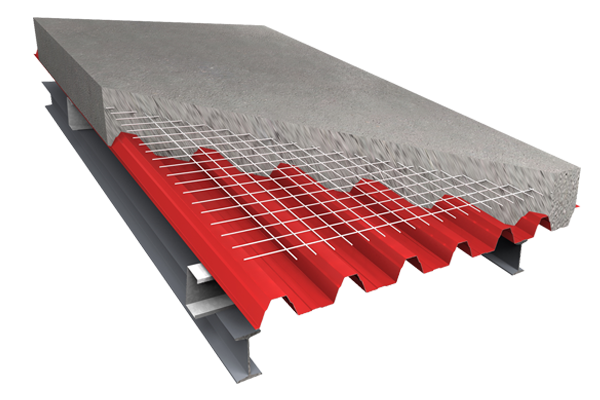

INTERMEDIATE FLOOR

SLAB FORMING EXAMPLE

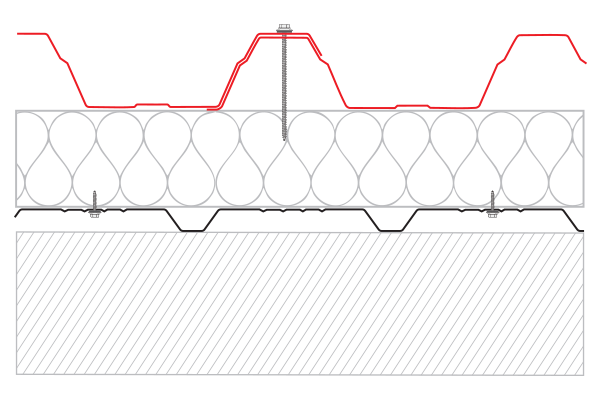

ROOF PROFILING

INSTALLATION CROSS SECTION

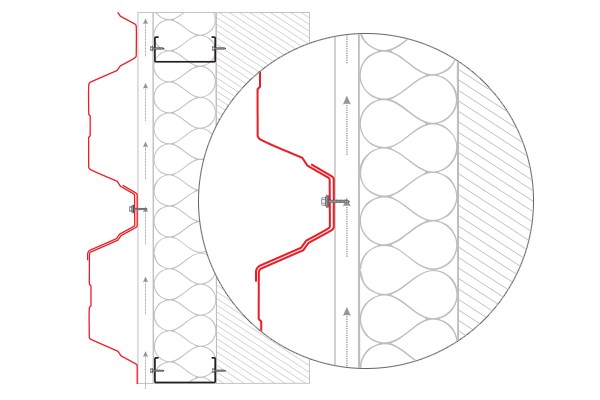

FACADE PROFILING

HORIZONTAL INSTALLATION CROSS SECTION

FACADE PROFILING

VERTICAL INSTALLATION CROSS SECTION

| Two supports | Permitted load (kN/m2) calculated by 1 meter / distance between supports | |||||||||||||

| span (m) | 1,00 | 1,25 | 1,50 | 1,75 | 2,00 | 2,25 | 2,50 | 2,75 | 3,00 | 3,25 | 3,50 | 3,75 | 4,00 | |

| Sheet metal thickness (mm) | Line | Line 1=ugib 200 / Linija 2=ugib 300 | ||||||||||||

| 0,50 | 1 | 8,22 | 5,26 | 3,65 | 2,68 | 2,06 | 1,62 | 1,32 | 1,07 | 0,83 | 0,65 | 0,52 | 0,42 | 0,35 |

| 2 | 8,22 | 5,26 | 3,65 | 2,68 | 1,86 | 1,31 | 0,95 | 0,72 | 0,55 | 0,43 | 0,35 | 0,28 | 0,23 | |

| 0,60 | 1 | 11,57 | 7,41 | 5,14 | 3,78 | 2,89 | 2,29 | 1,85 | 1,44 | 1,11 | 0,87 | 0,70 | 0,57 | 0,47 |

| 2 | 11,57 | 7,41 | 5,14 | 3,73 | 2,50 | 1,75 | 1,28 | 0,96 | 0,07 | 0,58 | 0,47 | 0,38 | 0,31 | |

| 0,70 | 1 | 15,37 | 9,84 | 6,83 | 5,02 | 3,84 | 3,04 | 2,45 | 1,84 | 1,41 | 1,11 | 0,89 | 0,72 | 0,60 |

| 2 | 15,37 | 9,84 | 6,83 | 4,75 | 3,18 | 2,23 | 1,63 | 1,23 | 0,94 | 0,74 | 0,59 | 0,48 | 0,39 | |

| 0,80 | 1 | 18,95 | 12,13 | 8,42 | 6,19 | 4,74 | 3,74 | 2,94 | 2,21 | 1,70 | 1,34 | 7,07 | 0,87 | 0,72 |

| 2 | 18,95 | 12,13 | 8,42 | 5,72 | 3,83 | 2,69 | 1,96 | 1,47 | 1,13 | 0,89 | 0,71 | 0,58 | 0,48 | |

| 1,00 | 1 | 25,23 | 16,15 | 11,21 | 8,24 | 6,31 | 4,98 | 3,85 | 2,89 | 2,22 | 1,75 | 1,40 | 1,14 | 0,94 |

| 2 | 25,23 | 16,15 | 11,21 | 7,48 | 5,01 | 3,52 | 2,56 | 1,93 | 1,48 | 1,17 | 0,93 | 0,76 | 0,63 | |

| Three supports | Permitted load (kN/m2) calculated by 1 meter / distance between supports | |||||||||||||

| span (m) | 1,00 | 1,25 | 1,50 | 1,75 | 2,00 | 2,25 | 2,50 | 2,75 | 3,00 | 3,25 | 3,50 | 3,75 | 4,00 | |

| Sheet metal thickness (mm) | Line | Line 1=ugib 200 / Linija 2=ugib 300 | ||||||||||||

| 0,50 | 1 | 8,38 | 5,37 | 3,73 | 2,74 | 2,09 | 1,65 | 1,34 | 1,10 | 0,93 | 0,79 | 0,68 | 0,59 | 0,52 |

| 2 | 8,38 | 5,37 | 3,72 | 2,74 | 2,09 | 1,65 | 1,34 | 1,10 | 0,93 | 0,79 | 0,68 | 0,59 | 0,52 | |

| 0,60 | 1 | 11,85 | 7,58 | 5,26 | 3,87 | 2,96 | 2,34 | 1,89 | 1,56 | 1,32 | 1,12 | 0,96 | 0,84 | 0,74 |

| 2 | 11,85 | 7,58 | 5,26 | 3,87 | 2,96 | 2,34 | 1,89 | 1,56 | 1,32 | 1,12 | 0,96 | 0,84 | 0,74 | |

| 0,70 | 1 | 15,03 | 9,62 | 6,67 | 4,90 | 3,75 | 2,96 | 2,40 | 1,98 | 1,67 | 1,42 | 1,22 | 1,06 | 0,94 |

| 2 | 15,03 | 9,62 | 6,67 | 4,90 | 3,75 | 2,96 | 2,40 | 1,98 | 1,67 | 1,42 | 1,22 | 1,06 | 0,94 | |

| 0,80 | 1 | 18,05 | 11,55 | 8,02 | 5,89 | 4,51 | 3,56 | 2,88 | 2,38 | 2,00 | 1,70 | 1,47 | 1,28 | 1,13 |

| 2 | 18,05 | 11,55 | 8,02 | 5,89 | 4,51 | 3,56 | 2,88 | 2,38 | 2,00 | 1,70 | 1,47 | 1,28 | 1,13 | |

| 1,00 | 1 | 23,17 | 14,83 | 10,30 | 7,56 | 5,79 | 4,57 | 3,70 | 3,06 | 2,57 | 2,19 | 1,89 | 1,64 | 1,44 |

| 2 | 23,17 | 14,83 | 10,30 | 7,56 | 5,79 | 4,57 | 3,70 | 3,06 | 2,57 | 2,19 | 1,89 | 1,64 | 1,44 | |

| Four supports | Permitted load (kN/m2) calculated by 1 meter / distance between supports | |||||||||||||

| span (m) | 1,00 | 1,25 | 1,50 | 1,75 | 2,00 | 2,25 | 2,50 | 2,75 | 3,00 | 3,25 | 3,50 | 3,75 | 4,00 | |

| Sheet metal thickness (mm) | Line | Line 1=ugib 200 / Linija 2=ugib 300 | ||||||||||||

| 0,50 | 1 | 10,48 | 6,70 | 4,65 | 3,42 | 2,62 | 2,07 | 1,67 | 1,38 | 1,16 | 0,99 | 0,85 | 0,74 | 0,65 |

| 2 | 10,48 | 6,70 | 4,65 | 3,42 | 2,62 | 2,07 | 1,67 | 1,37 | 1,06 | 0,83 | 0,67 | 0,54 | 0,45 | |

| 0,60 | 1 | 14,82 | 9,48 | 6,58 | 4,83 | 3,70 | 2,92 | 2,37 | 1,96 | 1,64 | 1,40 | 1,21 | 1,05 | 0,90 |

| 2 | 14,82 | 9,48 | 6,58 | 4,83 | 3,70 | 2,92 | 2,37 | 1,85 | 1,42 | 1,21 | 0,89 | 0,73 | 0,60 | |

| 0,70 | 1 | 18,78 | 12,02 | 8,34 | 6,13 | 4,69 | 3,71 | 3,00 | 2,48 | 2,08 | 1,78 | 1,53 | 1,33 | 1,15 |

| 2 | 18,78 | 12,02 | 8,34 | 6,13 | 4,69 | 3,71 | 3,00 | 2,35 | 1,81 | 1,42 | 1,14 | 0,93 | 0,76 | |

| 0,80 | 1 | 22,56 | 14,44 | 10,03 | 7,36 | 5,63 | 4,45 | 3,60 | 2,98 | 2,50 | 2,13 | 1,84 | 1,60 | 1,38 |

| 2 | 22,58 | 14,44 | 10,03 | 7,36 | 5,63 | 4,45 | 3,60 | 2,83 | 2,18 | 1,71 | 1,37 | 1,12 | 0,92 | |

| 1,00 | 1 | 28,96 | 18,53 | 12,87 | 9,45 | 7,24 | 5,72 | 4,63 | 3,83 | 3,21 | 2,74 | 2,36 | 2,06 | 1,80 |

| 2 | 28,96 | 18,53 | 12,87 | 9,45 | 7,24 | 5,72 | 4,63 | 3,71 | 2,85 | 2,25 | 1,80 | 1,46 | 1,20 | |

| Weight table Pan-T60/210 - galvanized steel | ||||

| Sheet metal thickness | Weight per sq. m. | |||

| 0,50 | 5,95 | |||

| 0,60 | 7,14 | |||

| 0,70 | 8,33 | |||

| 0,80 | 9,52 | |||

| 1,00 | 11,90 | |||

| Weight table Pan-T60/210 - aluminum | ||||

| Sheet metal thickness | Weight per sq. m. | |||

| 0,50 | x | |||

| 0,60 | 2,41 | |||

| 0,70 | 2,81 | |||

| 0,80 | 3,21 | |||

| 1,00 | 4,02 | |||

Downloading documents